DRIVE TORSION HOUSINGS

Posted: Fri Nov 07, 2008 1:20 pm

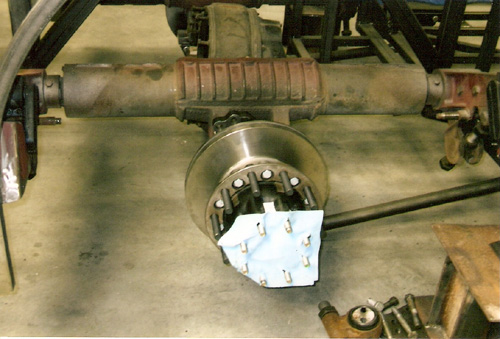

I was looking at the pictures that Wayne posted of his 1994 Eagle 15 and came across something that may be of concern.

After viewing the pictures that showed the drive axle torsion bars, I noticed that the keyways were welded on the top and the bottom of the housings. This can cause the housings to split. This was detected back in the early 80's when Eagle started having multiple failures due to split housings. Without notifying Eagle, the vendor made this change. The keyways should be welded on the sides. For some reason having them welded on the top and the bottom causes different stress loads on the inner spring. The problem did not always present itself. It mainly occurred from people not maintaining their suspension adjustment or carrying a loaded bus for extended trips and over poorly maintained roads. These keyways hold the inner spring in place. The inner spring assembly is made up of a steel tube which your fixing arms attach to, heavy duty rubber is bonded to that tube and then there are two steel half shell casings which are bonded to the outer part of the rubber. The half shell casings create a channel for the keyways in the housing so that when the spring assembly is pressed into the housing it will not turn. This allows the rubber to be wound up and gives you your smooth ride. So basically, your keyways are what keeps your coach up and therefore have a lot of stress on them.

If you are looking at buying an Eagle Coach, remember to inspect the housings on the drive axle, especially since your motorhomes are esentially loaded all of the time. I am not saying that if they have the welded keyways on the top and bottom that they will fail, but certainly they have a greater chance of failure.

Dan

After viewing the pictures that showed the drive axle torsion bars, I noticed that the keyways were welded on the top and the bottom of the housings. This can cause the housings to split. This was detected back in the early 80's when Eagle started having multiple failures due to split housings. Without notifying Eagle, the vendor made this change. The keyways should be welded on the sides. For some reason having them welded on the top and the bottom causes different stress loads on the inner spring. The problem did not always present itself. It mainly occurred from people not maintaining their suspension adjustment or carrying a loaded bus for extended trips and over poorly maintained roads. These keyways hold the inner spring in place. The inner spring assembly is made up of a steel tube which your fixing arms attach to, heavy duty rubber is bonded to that tube and then there are two steel half shell casings which are bonded to the outer part of the rubber. The half shell casings create a channel for the keyways in the housing so that when the spring assembly is pressed into the housing it will not turn. This allows the rubber to be wound up and gives you your smooth ride. So basically, your keyways are what keeps your coach up and therefore have a lot of stress on them.

If you are looking at buying an Eagle Coach, remember to inspect the housings on the drive axle, especially since your motorhomes are esentially loaded all of the time. I am not saying that if they have the welded keyways on the top and bottom that they will fail, but certainly they have a greater chance of failure.

Dan